News Center

-

R290 flammable R32 will explode? Talk about air conditioning refrigerants 2022-02-25

R290 flammable R32 will explode? Talk about air conditioning refrigerants 2022-02-25R290 flammable R32 will explode? Talk about air conditioning refrigerants

Refrigerant, also known as refrigerant and refrigerant, also has another well-known name, called snow seed. We often say that adding snow and Freon is to add new refrigerant to the air conditioner.

The refrigerant we are most familiar with is Freon. In our impression, freon is an environmentally friendly substance. If Freon leaks into the atmosphere, it will destroy the ozone layer of the atmosphere and form an ozone hole.

In fact, freon is not just a substance. Freon can be roughly divided into three categories, including chlorofluorohydrocarbons, hydrochlorofluorocarbons and hydrofluorocarbons. What will break the ozone layer is actually chlorofluorohydrocarbons in freon, and it is not fluorine that destroys ozone, but chlorine.

Although hydrochlorofluorocarbons also contain chlorine, their damage to the ozone layer is much lower than that of hydrochlorofluorocarbons. Hydrofluorocarbons have almost zero damage to the ozone layer because they do not contain chlorine. In addition, freon is also a greenhouse gas. Although the concentration of freon in the atmosphere is significantly lower than that of other greenhouse gases, its greenhouse effect is 3400 ~ 15000 times that of carbon dioxide.

Therefore, refrigerants usually introduce ozone layer destruction potential value (ODP) and global warming coefficient value (GWP) to measure their impact on the environment. The lower the ODP and GWP values are, the more environmentally friendly they are.

1. R22 refrigerant

R22 refrigerant belongs to hydrochlorofluorocarbons, and its chemical name is difluoro monochloromethane. R22 refrigerant is one of the most used refrigerants in the past. Most of our old air conditioners may use R22 refrigerant.

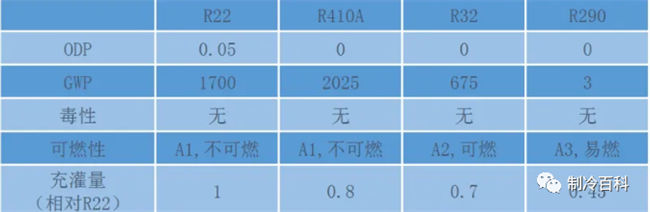

However, the ozone layer destruction potential (ODP) of R22 refrigerant is 0.05 and the global warming coefficient (GWP) is 1700, which will not only destroy the ozone layer, but also aggravate the greenhouse effect. For environmental reasons, R22 refrigerant is being phased out. According to the Montreal agreement, China is also phasing out products using R22 refrigerant, which only exists in some fixed frequency air conditioners.

2. R410A refrigerant

R410A refrigerant is a substitute of R22 refrigerant and is the most used refrigerant on the market. R410A refrigerant is a mixed refrigerant, which is a mixture of R32 (difluoromethane) and R125 (pentafluoroethane). The two substances are mixed in the ratio of 1:1.

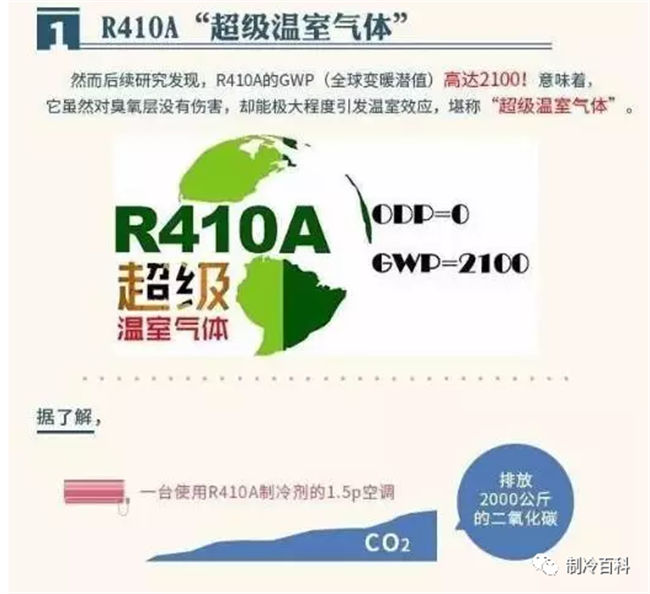

As a substitute for R22 refrigerant, R410A has an ozone layer destruction potential (ODP) of 0 and will not destroy the ozone layer. However, the global warming coefficient (GWP) of R410A is 2025. Many people say R410A is an environmentally friendly refrigerant, but it is not! Although R410A does not destroy the ozone layer, it will produce greenhouse gases, and the greenhouse gas effect even partially exceeds R22.

R410A refrigerant is a mixture of two substances in a certain proportion. In case of leakage, the manufacturer recommends refilling, so as to ensure that the mixing proportion of the two substances is consistent.

3. R32 refrigerant

R32 refrigerant belongs to hydrofluorocarbons and its chemical name is difluoromethane. The ozone layer destruction potential (ODP) of R32 refrigerant is 0 as that of R410A, while the global warming coefficient (GWP) of R32 is only 675, which is far lower than that of R410A.

In addition, R32 refrigerant has higher performance, less injection volume and lower cost than R410A. Moreover, R32's working pressure and performance parameters are close to R410A, and its maintenance and installation are basically the same. Adding fluorine again is the same as that of R22. You can add as much as you need, and you don't need to empty it all and refill it again.

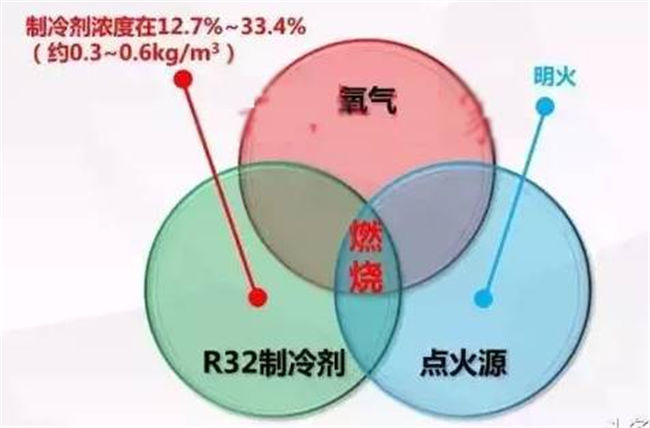

However, R32 has a disadvantage, that is, it is combustible, and the combustion grade is A2. This is undoubtedly the biggest stumbling block to the promotion of R32 refrigerant.

4. R290 refrigerant

R290 refrigerant is a more efficient and environmentally friendly refrigerant than R32 refrigerant. R290 does not belong to freon. Its chemical name is propane. Yes, it is the propane widely existing in natural gas. The ozone layer destruction potential (ODP) of R290 refrigerant is also zero, and its global warming coefficient (GWP) is very low, only 3.

It can be said that R290 refrigerant is the air conditioning refrigerant with the best environmental protection performance at present. However, R290 refrigerant is more flammable than R32, and its flammability is brought to grade A3. This puts forward higher requirements for all parts of the air conditioner, and it is required that the air conditioner can only be filled within 2p, and the air conditioner with large P number is limited. Therefore, this refrigerant has not been popularized at present. It is rumored in China that some manufacturers use R290 refrigerant for air conditioning products. It seems that some air conditioning products in Europe next door also use this refrigerant.

From the perspective of environmental protection, R32 and R290 refrigerants may be the most suitable refrigerants at present, but they are flammable and explosive! Some friends said, "environmental protection has nothing to do with me. I only care about safety."

Is that true? Let's look at the harm of excessive carbon emissions. Excessive carbon emissions will lead to global warming, produce greenhouse effect, accelerate the melting of ice and snow in the South and north poles, and cause the sea level to rise year by year; Cause extreme weather, such as typhoon, high temperature, rainstorm, debris flow, drought and other natural disasters; As a result, the temperature will rise, insect disasters will appear in some areas, the global food production may be seriously affected, and the output will gradually decline; The increase of carbon emissions will endanger people's health and quality of life. Who can survive the climate disaster?

As mentioned earlier, R32 refrigerant belongs to combustible substances. If combustible substances leak and encounter open fire, they will explode. At present, too many R32 air conditioning explosion accidents have been reported in the news. This undoubtedly makes consumers worried and afraid of R32 air conditioner, which has brought great obstacles to the renewal of air conditioning refrigerant.

R32 refrigerant is combustible. Combustion conditions: the concentration needs to reach a certain value and encounter open fire. The emergence of R32 air conditioner undoubtedly puts forward more standardized operation for air conditioner installers.

When installing the air conditioner, the length of the connecting pipe may be insufficient and the pipe needs to be lengthened. This situation is the most prone to problems and needs the most attention. First of all, the copper pipe should be lengthened, and the copper pipe needs to be reamed first. This step must be operated with a special pipe expander, and the hole must not be reamed with pointed nose pliers, so it is very easy to break and leak the copper pipe.

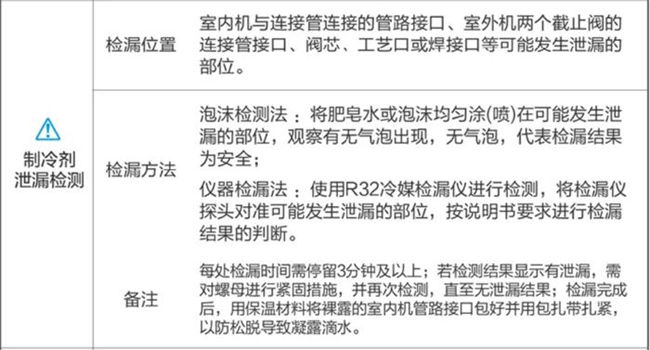

Another most important thing is the refrigerant leakage detection. Here, the refrigerant leakage detection steps in the Midea air conditioning manual are intercepted.

R32 product application precautions

1. If the copper pipe needs to be lengthened, the thickened copper pipe with thickness ≥ 0.8mm shall be used;

2. Pay attention to the difference between the installation and wiring and the pipe diameter of R22 refrigerant;

3. The internal machine and connecting pipe must be vacuumized and pressure maintained to ensure that the system has no leakage

4. Emptying is not allowed to replace vacuumizing;

5. For the extended copper pipe, add refrigerant according to the situation:

When the connecting pipe is less than or equal to 8m, no additional refrigerant is required. If the connecting pipe is more than 8m (subject to the liquid pipe), the refrigerant shall be added every 1m on the basis of 5m. The electronic scale must be used for quantitative addition. It is not allowed to add it by feeling or according to current, pressure and other parameters. -

Comparison of R22, R410A, R32 and R290 refrigerants 2021-11-24

Comparison of R22, R410A, R32 and R290 refrigerants 2021-11-24Comparison of R22, R410A, R32 and R290 refrigerants

At present, the refrigerant widely used in household air conditioning and heat pump is R22, which belongs to ozone depleting substance HCFC. According to the Montreal Protocol, China will eliminate the production and consumption of all manufacturing HCFC by 2030 [1]. The alternative refrigerants for R22 can be roughly divided into three categories:

The first type is HFC refrigerant, such as R410A (widely used) and R32 (potential refrigerant);

The second type is HC hydrocarbon refrigerant, such as R290 (potential refrigerant);

The third category is natural working medium carbon dioxide CO2 - it is generally not used in household air conditioning due to its high working pressure.

At present, the focus of household air-conditioning refrigerants mainly focuses on R22, R410A, R32 and R290. As the media of refrigeration industry, it is necessary for us to popularize their safety.

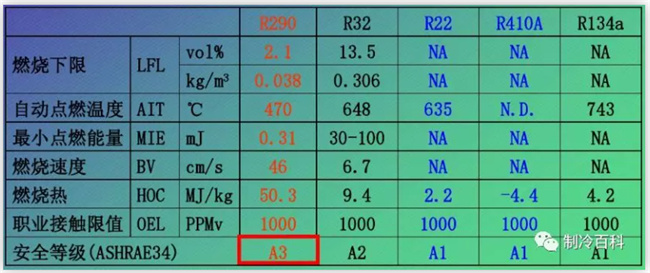

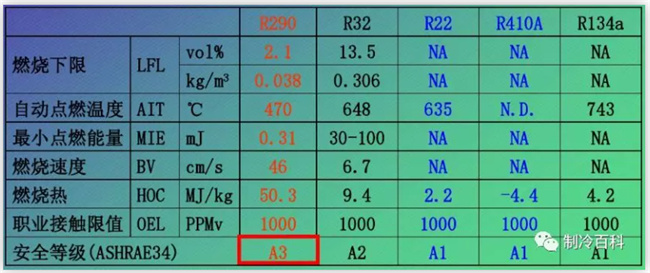

The safety of refrigerants mainly includes toxicity and flammability. The national standard refrigerant numbering method and safety classification GB / T 7778-2017 divides the toxicity of refrigerants into class A (low chronic toxicity) and class B (high chronic toxicity), and divides the flammability into class 1 (no flame propagation), class 2L (weak possibility), class 2 (possibility) and class 3 (flammability and explosion). According to GB / T 778-2017, refrigerant safety is divided into 8 categories: A1, A2L, A2, A3, B1, B2L, B2 and B3, of which A1 is the safest and B3 is the most dangerous.

R22: refrigerant to be eliminated

R22 is composed of chlorodifluoromethane (CHCLF2), which is non combustible and non explosive, with low toxicity and safety grade of A1. R22 ozone depleting potential ODP > 0, so it is not suitable for long-term use, and China will completely eliminate it by 2030.

R410A: alternative refrigerant for R22

R410A is composed of R32 and R125 in the proportion of 50% by mass. Among them, R32 (difluoromethane, CH2F2, A2L), R125 (pentafluoroethane, cf3chf2, A1) and a410a are safety grade A1. They also belong to non combustion, non explosion and low toxicity working fluids.

Compared with R22, R410A belongs to high-pressure refrigerant, which has higher requirements for equipment and system pressure strength, but it is conducive to reducing compressor displacement, reducing heat exchange copper pipe diameter and saving raw materials; R410A has better heat transfer and flow characteristics than R22, which is conducive to improve the operation efficiency of air conditioning and has obvious energy-saving effect. At present, it has been widely used.

ODP of R410A = 0, no ozone consumption; However, the global warming potential of R410A is GWP = 1730 (as a comparison, GWP of CO2 = 1), which plays a great role in promoting global warming. Therefore, R410A is not the final environmental protection refrigerant solution.

R32: future refrigerant competitors

The chemical composition of R32 is difluoromethane CH2F2, which has low toxicity, slight combustion and safety grade of A2L. R32 has the possibility of explosion, and its explosion limit is 14.4% - 29.3% [3]. The problem of low flammability needs to be solved in the application of household air conditioning.

The refrigeration performance of R32 is close to that of R410A. Under the same refrigeration capacity, the filling capacity of R32 is less than R410A (about 30% reduction), but the exhaust temperature is higher than R410A. R32 has ODP = 0 and GWP = 675. It is a green refrigerant and an important substitute for R22. At present, it has been widely used in household air conditioners in Europe, America, Japan and other countries.

R290: future refrigerant competitors

The chemical composition of R290 is propane (ch3ch2ch3), with little toxicity and flammability, and the safety grade is A3. The explosion limit of R290 is 2.1% - 10.0% [3], and the explosion point is much lower than R32.

ODP = 0 and GWP = 20 of R290 have little effect on global warming. It belongs to natural organic matter and can be obtained directly from liquefied petroleum gas with low price. R290 has good thermal performance, large gasification latent heat and less liquid filling capacity of the system. Under the same working conditions, the exhaust temperature can be 20 ℃ lower than R22, which is conducive to prolonging the service life of the compressor.

Last year, R290 gradually entered the field of vision. Many domestic enterprises have established R290 air conditioning production lines, and the national environmental protection department is also sparing no effort to promote the marketization process of R290 products [4]. At present, domestic support for R290 is greater than R32.

The biggest obstacle to the popularization and application of R290 is flammability. During use, safety measures need to be increased to ensure that its filling amount is controlled within the specified value of relevant regulations (standard iec60335-2-24: 2007) - at present, R290 is safe and controllable when used in household air conditioners < 1.5p; In addition, the leakage shall be reduced and the ability of leakage detection and response shall be improved.

Reference:

Source: Jianhuan world

[1] China Ozone Layer Protection Action Network: Notice on submitting the letter of intent for HCFC elimination and transformation project in industrial and commercial refrigeration and air conditioning industry in 2013

[2] Numbering method and safety classification of refrigerants (GB / T 7778-2017)

[3] Shi Lin, Zhu Mingshan. Reanalysis of R32 replacing R22 in household / commercial air conditioners [J]. Journal of refrigeration, 2010,01:1-5

[4] China home appliance network: the first batch of R290 air conditioners in China were officially listed in Shenzhen

-

Causes of compressor overcurrent 2021-10-27

Causes of compressor overcurrent

In short, there are three reasons for the over-current of the compressor:

1. The condensation pressure of the refrigeration system is too high;

2. Too much refrigerant in the refrigeration system;

3. The compressor is short of refrigerant oil

Let's explain in detail below:

Poor external heat dissipation

Short circuit of air return and exhaust of external machine: if the external machine is installed in closed balcony, narrow aisle, indoor and other non ventilated places, there are obstacles in front of the air outlet.

The air volume of the external unit is small and the heat dissipation speed is slow: if the condenser of the external unit is too dirty or blocked by dust and oil, the fan motor speed is slow, the fan capacitance becomes small, and the surrounding temperature of the external unit is high.

2、 External supply voltage factor

The low or high power supply voltage will cause the high working current of the compressor, while the low voltage in China accounts for the vast majority, especially at the peak of power consumption.

If the power supply voltage (i.e. the voltage before startup) is too low, the user shall be asked to rewire. If the voltage is about 190V, it can be considered to install a voltage regulator. If it is too low, it will be invalid.

Check the voltage drop after startup: under normal conditions, the voltage drop is only more than ten volts. If the voltage drop is too large, the power line shall be thickened or rewired, and the faults such as poor line contact shall be eliminated.

3、 Refrigeration system failure

Air mixed in the refrigeration system: if there is air in the system, the air often accumulates in the upper part of the condenser, because it cannot pass through the accumulator of the condenser. Whether there is air in the system can generally be determined by the pulsation of the system pressure. If there is air in the system, it should be evacuated and fluorinated again.

Excessive fluorine: the compressor is overloaded for a long time, which will eventually lead to over-current tripping of the compressor. In this case, some fluorine should be released to the.

4、 High housing / internal temperature

Poor lubrication of the compressor: the height difference between indoor and outdoor units is greater than 5m, no oil return bend is made, or only an oil return bend is made on one pipe, the system can not return oil smoothly, the temperature of the compressor rises slowly during operation due to lack of lubrication, and finally leads to overheating and tripping.

There are too many impurities and moisture in the system: the lubricating oil is deteriorated and carbonized, which can not play a normal effect, resulting in a sharp rise in the temperature of the compressor, overheating and tripping. This kind of situation usually occurs on the machine that has been repaired or has been used for a long time. If the substances in the inspection system are black, it must exist. At this time, clean the system with nitrogen, replace the compressor and capillary assembly, and evacuate and add fluorine again.

5、 Poor cooling effect of compressor

The system has too little fluorine, and the temperature of the compressor is very high during operation. The high-temperature coil is cooled by the inhaled refrigerant. If there is too little fluorine, the system flow will be small and can not meet 100% of the load of the evaporator, resulting in the increase of suction superheat. In addition, the small suction flow of the compressor will greatly reduce the cooling efficiency. In this way, long-term operation can lead to the thermal protection of the compressor.

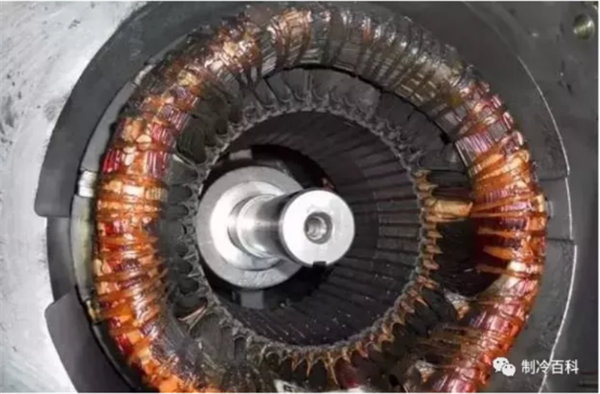

Common causes of compressor coil burning

1. The air conditioning compressor starts frequently

In the process of starting the air conditioning compressor, a step-down starting circuit is generally set, but the starting current will exceed several times of the rated current, and the starting temperature of the air conditioning compressor motor rises very fast. If the air conditioner temperature is not set properly, the refrigeration temperature is too low and the heating temperature is too high, the air conditioning compressor will be turned on and off frequently, which will shorten the service life of the air conditioning compressor.

2. The air conditioning compressor starts frequently

Poor power supply voltage quality, such as too high or too low voltage, will have a negative impact on the motor of the air conditioning compressor, especially if it is used beyond the rated voltage range of the air conditioning compressor. Long term operation will make the motor of the air conditioning compressor in an inefficient and overheated state, resulting in poor insulation and burning of the motor winding. In addition, the three-phase voltage or current imbalance will also increase the motor loss (iron loss and copper loss), the motor coil temperature of the air conditioning compressor is too high, the superheater protection is improper, and the insulation of the air conditioning compressor motor is burned, resulting in the short circuit of the air conditioning motor coil.

3. The refrigeration system was not cleaned up after the compressor was burnt out

For the air conditioning and refrigeration system with compressor burning fault, the refrigeration system must be cleaned thoroughly. When the air conditioning compressor motor is burned, strong acid will be generated and stay in the system. If it is not cleaned, when the new air conditioning compressor motor runs, the residual acid will corrode the insulation layer of the air conditioning compressor motor, resulting in the burning of the new air conditioning compressor.

4. Insufficient cleanliness of copper pipe system

It contains water, which will also lead to poor insulation of air conditioning compressor motor; Water, refrigerant and refrigeration oil circulate in the system. After changes in high temperature and low temperature, acidic substances will be produced, which will damage the insulation layer of the motor. After a long working time, the motor of the air conditioning compressor will be burned.

5. Poor cooling of compressor

The return air temperature is too high or the return air volume is too low, resulting in insufficient cooling of the compressor motor coil. For air-cooled heat pump units, this happens more, and too high return air temperature will also lead to too high exhaust temperature, resulting in a series of air-conditioning compressor problems.

6. Compressor starting contactor failure

The contact resistance of the contactor is too large or sintered, resulting in short circuit and burning of the air conditioning compressor motor, or poor line contact and large starting current, which is easy to burn the air conditioning compressor.

7. Short circuit caused by metal chips

The metal chips mixed in the winding are the culprit of short circuit and low grounding insulation value. The normal vibration during the operation of the compressor and the twisting of the winding under the action of electromagnetic force during each startup will promote the relative movement and friction between the metal chips mixed between the windings and the winding enamelled wire. Sharp metal chips will scratch the insulating layer of enameled wire and cause short circuit.

-

What is the difference between the R22 and R404A cold storage systems? 2021-08-30

What is the difference between the R22 and R404A cold storage systems?

In the past, many R22 refrigerators used R22 refrigeration, but now more and more R404A refrigerant is used, so why do cold storage use relatively high R404A refrigerant?What is the difference between the R22 and R404A cold storage systems?

First of all, R22 refrigerant is a non-environmentally friendly refrigerant, and developed countries in Europe and America have been eliminated from use.Although R404A GWP refrigerant is high, not a really environmentally friendly refrigerant, but relatively R22 is more environmentally friendly.In addition, the latent heat of R404A refrigerant is larger than R22, the thermal efficiency and refrigeration efficiency are higher, the system circulation volume is small, the filling amount is less than R22, the refrigeration speed is faster than R22, and the corresponding temperature under the same pressure is lower than R22. Therefore, many refrigeration equipment is used in cold storage with R404A refrigerant.

R22 and R404A cold storage system differences

1, R404A cold storage system and lubricating oil itself are very soluble with water, so the requirements for water and residues and cleanliness of the system are improved compared with the R22 cold storage system. Water control and impurity control of R404A system are a relatively important index, and the corresponding filter device in the system should be changed.

2, R404A cold storage system is about 1.2 times that of R22, the mass flow rate is about 1.5 times that of R22, and the exhaust flow rate increases and the resistance increases.In general, the condenser has a heat exchange capacity of 20% ~ 30% greater than the R22.

3,The saturation temperature of R404A cold storage system at the same temperature is different from R22, so the action mechanism of R404A thermal expansion valve is different from that of R22.At the same time, due to the R404A refrigerant and the solvent of lubricant to the different sealing materials, the sealing materials of the expansion valve should also be changed accordingly. Therefore, the R404A special expansion valve should be selected in the selection of thermal expansion valve.

4, Due to the high saturation pressure of R404A cold storage system than R22, the higher pressure vessel pressure resistance in the system, such as reservoir and gas-liquid separator.The safety valve and fuse setting value installed on the system accessories should also be changed accordingly.Since the gas density of R404A is about 50% greater than R22 under the same exhaust amount, the pipe diameter is larger than R22 using the R404A cold storage system.

5, The same compressor, the current of the R404A cold storage system should be greater than R22,, so the line diameter of the AC contactors, heat relays and cables of the compressor shall be adjusted.For system protection, the high pressure pressure switch set is adjusted from 2.45MPa to 2.7MPa.

6, Because the saturation pressure of the 404A cold storage system is different from R22, the air tightness test pressure is greater than R22. The vacuum is higher than R22, water content is lower than R22. The refrigerant shall be filled in liquid form to prevent the R404A configuration changes.

7, R404A is non-coboiling mixed work quality, the composition concentration of non-coboiling mixture varies with temperature and pressure, which brings certain difficulties to the production, debugging and maintenance of the refrigeration system, will also have a certain impact on the system heat conduction performance, especially when the refrigerant leakage, the system refrigerant needs to be completely replaced, so as to ensure the proportion of the mixed components, and to achieve the design refrigeration effect, otherwise it will get worse and worse.

The 8, R404A cold storage system, different from R22 lubricating oil, must be replaced by R22 with PVE ester oil.Eester lubricating oil and water have high affinity and poor dehydration, so contact with external air should be avoided as far as possible in use. The container shall be used as soon as possible, sealed, stay away from oxidant, strong alkali and strong acid and kept in well ventilated place; avoid contact with skin and eyes and vapor and spray. -

The reason of compressor overflowing 2021-07-16

The reason of compressor overflowing

In short, there are three reasons for the overflow of the compressor:

1.The condensation pressure of the refrigeration system is too high;

2.Too much refrigerant in the refrigeration system;

3.The compressor is missing the frozen oil.

Details are given below:

1、Poor heat dissipation of the external machine

Short circuit to external machine return and exhaust air:Such as the external machine is installed in the enclosed balcony, the narrow corridor, the house and other unventilated places, there are obstacles in front of the tuyere.

The external machine air volume is small and the cooling speed is slow: if the external machine condenser is too dirty or blocked by dust and oil, the fan motor speed is slow, the fan capacitance becomes smaller, and the temperature around the external machine is high.

2、External power supply voltage factor

The supply voltage is low or high, both cases will cause compressor high working current, and the domestic voltage is the majority, especially when the peak electricity.

If the power supply voltage (i. e. voltage before startup) is too low: let the user to rewiring, if the voltage is about 190V, consider the voltage stabilizer, if it is too low is invalid.

Check the pressure drop after startup: under normal circumstances, the pressure drop is only a dozen volts, and the pressure drop is too large, the power line or rewiring, and faults such as poor line contact should be eliminated.

3、Refrigeration system failure

When mixed with air in the refrigeration system: if there is air in the system, the air is often stored in the upper part of the condenser, because it cannot be determined through the condenser and whether there is air in the system. If there is air in the system, fluorine treatment should be evacuated.

Excessive fluoride: the compressor is in an overload state for a long time, which will eventually lead to the compressor overload jump machine. This condition shall release a partial fluorine to.

4、Housing / high internal temperature

Poor lubrication of the compressor: the height difference of indoor and external machines is more than 5 meters did not return the oil bend, or made the return oil bend on only one pipe, and the system can not return the oil smoothly. The temperature of the compressor slowly rises during the operation due to lack of lubrication, which finally leads to overheating jump.

Impurities in the system, too much water: make the lubricating oil deteriorate, carbonization, can not play a normal effect, resulting in the compressor temperature rise sharply and overheating jump machine. This generally occurs on the repaired machine or used machine for a long time. If the substances in the inspection system is black, apply nitrogen cleaning system, replace the compressor, capillary assembly, and take time to add fluorine.

5、The compressor cooling effect is poor

The system is too little fluorine, the compressor working temperature is very high, the high temperature coil is by inhaled refrigerant to cool, if the fluorine is too little, the system flow is small, can not meet 100% of the evaporator load, resulting in the suction heat increase, plus the compressor intake flow is small, cooling efficiency is greatly reduced, so that a long operation can lead to compressor thermal protection.

Common causes of compressor coil burning

1, air conditioning compressor starts frequently

During the starting process of air conditioning compressor, there is generally a voltage start-up circuit, but the starting current will exceed several times the rated current, and the starting temperature of air conditioning compressor motor rises very fast. If the air conditioning temperature is not set properly, the cooling temperature is too low, and the heating temperature is too high, the air conditioning compressor will switch on and off frequently, which will shorten the life of the air conditioning compressor.

2, air conditioning compressor starts frequently

Bad supply voltage quality such as too high or too low, have a bad impact on the air conditioning compressor motor, especially beyond the rated voltage range of the air conditioning compressor, the most improper, long-term operation makes the air conditioning compressor motor in an inefficient overheating state, resulting in poor insulation, motor windings burned. In addition, the three-phase voltage or current imbalance will also cause increased motor loss (iron and copper loss), the air conditioning compressor motor coil temperature is too high, the superheater protection is improper, the insulation of the air conditioning compressor motor burned, resulting in short circuit burning of the air conditioning motor coil.

3, compressor burned down

For air conditioning refrigeration system once compressor burning fault, must clean up the refrigeration system thoroughly, air conditioning compressor motor burning will have strong acid generation and stay in the system, if not clean, when the new air conditioning compressor motor operation, residual acid substances will corrode the air conditioning compressor motor insulation, causing the new air conditioning compressor burning.

4, copper system is not clean

It contains water, water will also cause poor insulation of the air conditioning compression motor; water and refrigerant and frozen oil circulation in the system, after high temperature and low temperature and other state changes, will produce acid substances, and then destroy the insulation layer of the motor, a long working time, the air conditioning compressor motor will be burned.

5, compressor is poorly cooled

The return temperature is too high or low to cool the compressor motor coil. The air-cooled heat pump unit occurs more frequently, and the high return temperature will also lead to too high exhaust temperature, resulting in a series of air conditioning compressor problems.

6, compressor start contactor fault

Contactor contact resistance is too large or sintering, causing short circuit burning of the air-conditioning compressor motor, or poor line contact, and the large starting current can easily burn the air-conditioning compressor.

7, metal chips

The mixed metal chips in the winding are responsible for short circuit and low ground insulation. Normal vibration of the compressor during the operation of each startup and the winding twisted by electromagnetic force cause the relative movement and friction between the metal debris between the winding and the winding paint line. Sharp metal chips can scratch the paint wrap wire insulation, causing a short circuit.

-

What's the difference between AC inverter and DC inverter air conditioner? 2021-05-28

What's the difference between AC inverter and DC inverter air conditioner? 2021-05-28What's the difference between AC inverter and DC inverter air conditioner?

Household air conditioning is divided into fixed frequency and frequency conversion, the difference between the two lies in the control mode of compressor speed. Constant speed air conditioning compressor speed is fixed, not variable, this kind of air conditioning refrigeration (heat) output of cold (heat) is also fixed, not adjustable, so the temperature adjustment can only be adjusted by the compressor on or off.

The compressor speed of frequency conversion air conditioner is not fixed and can be changed. The output cold (heat) quantity of refrigeration (heat) can also be adjusted. Therefore, the output cold quantity of air conditioner can be changed by changing the compressor speed. Frequency conversion air conditioning is divided into DC frequency conversion and AC frequency conversion, and their concepts and control methods are different. Next, we will analyze their advantages and disadvantages and differences one by one.

1、 Advantages and disadvantages of variable frequency air conditioner

1. Advantages of variable requency air conditioning

① Energy saving and power saving: due to the function of internal frequency converter, the compressor will not start frequently, and the starting current is also very small;

② Intelligent adjustment of room temperature: the compressor changes the speed intelligently according to the temperature change, so as to keep the room temperature at a constant value and make the human body feel more comfortable;

③ Low noise: compared with the constant frequency air conditioner, the noise is lower, which is caused by the unbalance of the compressor, and the frequent start-up noise of the compressor is higher than that of the constant frequency air conditioner;

④ Wide voltage operation: because the constant frequency air conditioner needs starting capacitor to start, the voltage should not be too low, but the variable frequency can realize soft start, which is not very strict on voltage input, especially suitable for rural areas with unstable voltage.

⑤ Fast cooling (heating): due to the special electronic expansion and throttling technology used in the frequency conversion air conditioner, and the high power operation when the temperature difference is large, the temperature rises or falls rapidly.

2. Disadvantages of variable frequency air conditioning

① Maintenance is difficult and expensive: because frequency conversion air conditioner has more frequency converters than ordinary air conditioner, and the circuit and structure are more complex, frequency conversion air conditioner is easy to break down. Although the production process has been improved, compared with constant frequency air conditioner, its failure probability is much higher, the price is higher, the maintenance is more expensive, and the maintenance cost is much higher. This is also where many refrigeration technicians make complaints about tucks.

② High price: due to the complexity and advantages of frequency conversion air conditioning, the price is about 1000 yuan more than ordinary air conditioning;

③ Other disadvantages: for example, it needs to be running all the time to reflect its energy saving and power saving characteristics.

2、 Difference between AC frequency conversion and DC frequency conversion

1. DC frequency conversion air conditioner

Working principle of DC frequency conversion air conditioner: convert 50 Hz AC power into DC power and send it to the main circuit of power module. The power module is also controlled by microcomputer. The difference is that the output of the module is DC power with variable voltage, and the compressor uses DC motor. Therefore, DC frequency conversion air conditioner can also be called full DC variable speed air conditioner.

The rotor of DC variable frequency compressor is made of rare earth permanent magnet material. Its working principle is: the rotating magnetic field produced by stator acts directly with the permanent magnetic field of rotor to realize the operation of compressor. The speed of the motor can be changed by changing the DC voltage sent to the motor. DC inverter air conditioner has no inverter link, which is more power-saving than AC inverter.

The efficiency of DC variable frequency compressor is 10% - 30% higher than that of AC variable frequency compressor, and the noise is 5 DB-10 dB lower. However, the cost of DC inverter air conditioning is higher than that of AC inverter air conditioning.

2. AC variable frequency air conditioner

The working principle of AC frequency conversion air conditioner: AC frequency conversion technology is a technology that changes the power frequency through the frequency converter, so as to change the speed of the compressor. The conversion from AC to DC is carried out through the frequency converter, and then the conversion from DC to AC is carried out through the frequency converter, so as to control the speed of the AC motor. The control of the inverter is to transmit the indoor temperature information to the microcomputer through the sensor, and output a certain frequency waveform to control the frequency of the inverter.

AC motor can be operated in high temperature, flammable environment, and do not need to clean the dirt of carbon brush regularly, but it is difficult to control the speed. AC motor is a rotating magnetic field movement, and the conductor does not move. Although the manufacture is relatively cheap, the starting performance and speed regulation performance of AC motor are poor.

The advantage of DC motor is that it is simpler in speed control, less power and quieter. The structure of DC motor is complex, the manufacture is difficult and the price is high. DC motor is the magnetic field does not move, the conductor moves in the magnetic field. Compared with AC, DC motor is more energy-saving and environment-friendly.

Full DC variable frequency air conditioning refers to the three core motors of air conditioning: variable frequency compressor motor, indoor fan motor and outdoor fan motor. They all use powerful DC motor. With the inherent advantages of DC motor and the organic combination of microcomputer technology, the air conditioning performance is further improved, the room temperature fluctuation is small, and the comfort is better, It is insensitive to the fluctuation of power supply voltage, and the cooling capacity varies from 35% to 117%.

3、 How to choose frequency conversion and fixed frequency?

The choice of frequency conversion or fixed frequency should be decided by itself. Frequency conversion can save electricity a lot of times, but for continuous work, if a period of time is less than 5 hours, and the month is not long, then its energy saving can not be reflected too much, it is not as good as constant frequency. If you pursue comfort, frequency conversion is the best choice.

If you don't use the air conditioner very frequently, you don't have to ask for comfort. At this time, you can consider fixed frequency, because the price is relatively cheap and the maintenance is easy. As for whether to choose a domestic brand or a Japanese brand, Xiaobian is still saying that, according to his own actual situation, it's good to have money to buy high-end brands and no money to buy domestic brands. After all, the price is much cheaper.