News Center

- Causes of compressor overcurrent

- date: 2021-10-27 hits:1746

-

Causes of compressor overcurrent

In short, there are three reasons for the over-current of the compressor:

1. The condensation pressure of the refrigeration system is too high;

2. Too much refrigerant in the refrigeration system;

3. The compressor is short of refrigerant oil

Let's explain in detail below:

Poor external heat dissipation

Short circuit of air return and exhaust of external machine: if the external machine is installed in closed balcony, narrow aisle, indoor and other non ventilated places, there are obstacles in front of the air outlet.

The air volume of the external unit is small and the heat dissipation speed is slow: if the condenser of the external unit is too dirty or blocked by dust and oil, the fan motor speed is slow, the fan capacitance becomes small, and the surrounding temperature of the external unit is high.

2、 External supply voltage factor

The low or high power supply voltage will cause the high working current of the compressor, while the low voltage in China accounts for the vast majority, especially at the peak of power consumption.

If the power supply voltage (i.e. the voltage before startup) is too low, the user shall be asked to rewire. If the voltage is about 190V, it can be considered to install a voltage regulator. If it is too low, it will be invalid.

Check the voltage drop after startup: under normal conditions, the voltage drop is only more than ten volts. If the voltage drop is too large, the power line shall be thickened or rewired, and the faults such as poor line contact shall be eliminated.

3、 Refrigeration system failure

Air mixed in the refrigeration system: if there is air in the system, the air often accumulates in the upper part of the condenser, because it cannot pass through the accumulator of the condenser. Whether there is air in the system can generally be determined by the pulsation of the system pressure. If there is air in the system, it should be evacuated and fluorinated again.

Excessive fluorine: the compressor is overloaded for a long time, which will eventually lead to over-current tripping of the compressor. In this case, some fluorine should be released to the.

4、 High housing / internal temperature

Poor lubrication of the compressor: the height difference between indoor and outdoor units is greater than 5m, no oil return bend is made, or only an oil return bend is made on one pipe, the system can not return oil smoothly, the temperature of the compressor rises slowly during operation due to lack of lubrication, and finally leads to overheating and tripping.

There are too many impurities and moisture in the system: the lubricating oil is deteriorated and carbonized, which can not play a normal effect, resulting in a sharp rise in the temperature of the compressor, overheating and tripping. This kind of situation usually occurs on the machine that has been repaired or has been used for a long time. If the substances in the inspection system are black, it must exist. At this time, clean the system with nitrogen, replace the compressor and capillary assembly, and evacuate and add fluorine again.

5、 Poor cooling effect of compressor

The system has too little fluorine, and the temperature of the compressor is very high during operation. The high-temperature coil is cooled by the inhaled refrigerant. If there is too little fluorine, the system flow will be small and can not meet 100% of the load of the evaporator, resulting in the increase of suction superheat. In addition, the small suction flow of the compressor will greatly reduce the cooling efficiency. In this way, long-term operation can lead to the thermal protection of the compressor.

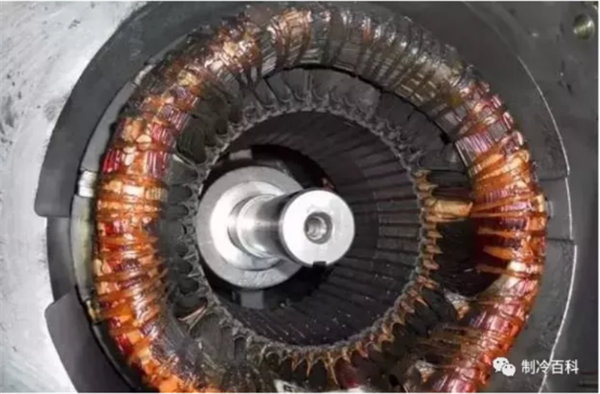

Common causes of compressor coil burning

1. The air conditioning compressor starts frequently

In the process of starting the air conditioning compressor, a step-down starting circuit is generally set, but the starting current will exceed several times of the rated current, and the starting temperature of the air conditioning compressor motor rises very fast. If the air conditioner temperature is not set properly, the refrigeration temperature is too low and the heating temperature is too high, the air conditioning compressor will be turned on and off frequently, which will shorten the service life of the air conditioning compressor.

2. The air conditioning compressor starts frequently

Poor power supply voltage quality, such as too high or too low voltage, will have a negative impact on the motor of the air conditioning compressor, especially if it is used beyond the rated voltage range of the air conditioning compressor. Long term operation will make the motor of the air conditioning compressor in an inefficient and overheated state, resulting in poor insulation and burning of the motor winding. In addition, the three-phase voltage or current imbalance will also increase the motor loss (iron loss and copper loss), the motor coil temperature of the air conditioning compressor is too high, the superheater protection is improper, and the insulation of the air conditioning compressor motor is burned, resulting in the short circuit of the air conditioning motor coil.

3. The refrigeration system was not cleaned up after the compressor was burnt out

For the air conditioning and refrigeration system with compressor burning fault, the refrigeration system must be cleaned thoroughly. When the air conditioning compressor motor is burned, strong acid will be generated and stay in the system. If it is not cleaned, when the new air conditioning compressor motor runs, the residual acid will corrode the insulation layer of the air conditioning compressor motor, resulting in the burning of the new air conditioning compressor.

4. Insufficient cleanliness of copper pipe system

It contains water, which will also lead to poor insulation of air conditioning compressor motor; Water, refrigerant and refrigeration oil circulate in the system. After changes in high temperature and low temperature, acidic substances will be produced, which will damage the insulation layer of the motor. After a long working time, the motor of the air conditioning compressor will be burned.

5. Poor cooling of compressor

The return air temperature is too high or the return air volume is too low, resulting in insufficient cooling of the compressor motor coil. For air-cooled heat pump units, this happens more, and too high return air temperature will also lead to too high exhaust temperature, resulting in a series of air-conditioning compressor problems.

6. Compressor starting contactor failure

The contact resistance of the contactor is too large or sintered, resulting in short circuit and burning of the air conditioning compressor motor, or poor line contact and large starting current, which is easy to burn the air conditioning compressor.

7. Short circuit caused by metal chips

The metal chips mixed in the winding are the culprit of short circuit and low grounding insulation value. The normal vibration during the operation of the compressor and the twisting of the winding under the action of electromagnetic force during each startup will promote the relative movement and friction between the metal chips mixed between the windings and the winding enamelled wire. Sharp metal chips will scratch the insulating layer of enameled wire and cause short circuit.

-

pre:Comparison of R22, R410A, R32

next:What is the difference between - back