News Center

-

Flammable and explosive R290 refrigerant, COME IN TO UNDERSTAND! 2020-05-05

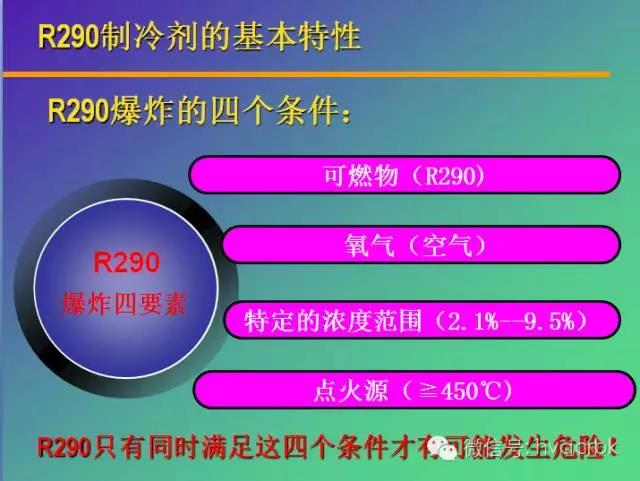

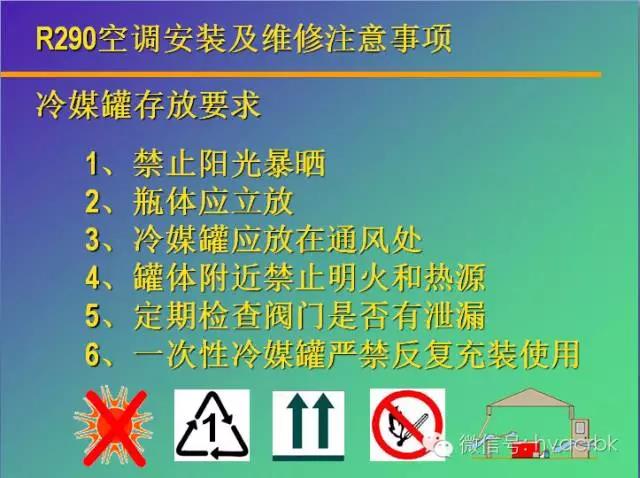

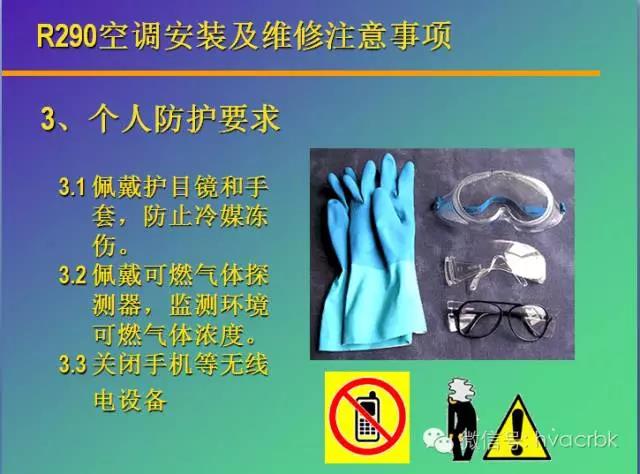

Flammable and explosive R290 refrigerant, COME IN TO UNDERSTAND! 2020-05-05Propane, a hydrocarbon refrigerant, Molecular Formula C3H8, appearance colorless gas, pure odorless, slightly soluble in water, soluble in ether, ethanol, flashpoint °c-104. The upper explosion limit is% v / V 9.5, the lower explosion limit is% v / V 2.1, the relative density of air is 11.56, the heat of combustion is KJ / Mol: 2217.8, the ignition temperature is 450 ~ 470 °C. Note: Flash Point: the temperature at which a mixture of steam and air on the surface of a flammable liquid first occurs in contact with fire. Health Hazards: SIMPLE ASPHYXIA and anesthesia. Short-term exposure to 1% propane does not cause symptoms; concentrations below 10% cause only mild dizziness; high concentrations of exposure can lead to anesthesia, loss of consciousness; extremely high concentrations can lead to suffocation. Hazard characteristics: Flammable Gas, mixed with air can form explosive mixture, heat source and open fire with the risk of combustion and explosion, Safety Class A 3. Small charge: R290 refrigerant dosage is only R22, R410A of 40% ~ 55% , less dosage, more economic. Energy Saving: Low freezing point, higher latent heat of evaporation, faster cooling rate per unit time; less isentropic compression than work, easier compressor work, longer compressor life; small molecular weight, good fluidity, lower conveying pressure, reduced the load of the compressor. Using R290 refrigerant, the energy saving rate can reach 15 ~ 30% .

Article Collation from the "encyclopedia of refrigeration"

cold and warm life, Binger accompanied ! -

Fault analysis of compressor liquid strike 2020-01-10

Fault analysis of compressor liquid strike 2020-01-10The phenomenon that liquid refrigerants and / or lubricants in the Refrigeration System Damage the suction valve plate when they are sucked into the cylinder of the compressor, and they are not discharged rapidly after entering the cylinder, the phenomenon of transient high hydraulic pressure produced by the compression of a Piston near TDC is often referred to as a hydraulic blow. Hydraulic blow can cause damage to compressed components such as valves, Pistons, connecting rods, crankshafts, Piston pins, etc. in a short period of time and is a deadly Reciprocating compressor. The occurrence of a liquid strike can be prevented by reducing or preventing the liquid from entering the cylinder, so the liquid strike can be completely avoided.

Usually, fluid percussion can be divided into two parts or processes:

• first, when more liquid refrigerants, lubricants, or a mixture of both enter the compressor cylinder at a higher speed with suction, due to the impact and incompressibility of the liquid, it can cause excessive bending or fracture of the Suction Valve Plate;

secondly, when the liquid in the cylinder which has not been evaporated and discharged in time is compressed by the Piston, the huge pressure appears in an instant and causes the deformation and damage of the stressed parts. These forces include Suction and Exhaust Valve Plate, Valve Plate, valve plate gasket, Piston (top) , Piston Pin, connecting Rod, crankshaft, bearing, and so on.

The process and phenomenon of refrigeration compressor liquid strike

Suction Valve piece broken: The compressor is a compressed gas machine. Typically, the Piston compresses the gas 1,450 times per minute (for a semi-hermetic compressor) or 2,900 times per minute (for a fully hermetic compressor) , that is, it takes 0.02 seconds or less to complete an intake or exhaust process. The size of the suction and exhaust holes on the Valve Plate and the elasticity and strength of the Suction and exhaust valve plates are designed according to the flow of gas. From the point of view of the force on the Valve Plate, the impact force produced by the gas flow is relatively uniform.

A liquid is tens or even hundreds of times as dense as a gas, so it flows with much more momentum than a gas and produces much more impact. The flow in the cylinder with more droplets in the suction is two-phase flow. The impact of two-phase flow on the suction valve plate is not only strong but also high frequency, just like a typhoon with pebbles hitting on the glass window, its destructiveness is self-evident. The fracture of suction valve is one of the typical characteristics and process of fluid percussion.

Refrigeration compressor connecting Rod Fracture: compression stroke time of about 0.02 seconds, and the exhaust process will be shorter. Droplets or liquid in the cylinder must be discharged from the vent in such a short time, and the speed and momentum are great. The situation of the exhaust valve piece is the same as that of the suction valve piece. The difference is that the exhaust valve piece is not easily broken because of the limited position plate and the spring plate support. When the impact is serious, the limit plate will also be warped.

If the liquid does not evaporate and leave the cylinder in time, the Piston compresses the liquid near TDC, which, because of its short duration, appears to be an impact, and a metallic knock is heard in the cylinder head. The compressed liquid is another part or process of the fluid percussion phenomenon.

The high pressure produced in the moment of liquid impact is very destructive. Besides the bending and even breaking of the connecting Rod, other compression force components (Valve Plate, Valve Plate Pad, crankshaft, Piston, Piston Pin, etc.) will also be deformed or damaged, but they are often neglected, or it could be confused with excessive exhaust pressure. It is easy to find bent or broken connecting rods and replace them without checking other parts for deformation or damage, thus laying the foundation for future failures.

The fracture of the connecting Rod caused by the hydraulic blow is distinguishable from that caused by the holding of the axle and the Piston biting the cylinder. First of all, the connecting rod bending or breaking caused by hydraulic impact in a short period of time, the Piston and crankshaft at both ends of the connecting rod move freely, generally there will not be serious wear and tear caused by holding the shaft or biting the cylinder. Although the Broken Suction Valve fragment occasionally causes severe scratches on the Piston and cylinder surfaces, surface scratches are quite different from lubrication failures that cause wear.

Secondly, the break of connecting Rod caused by hydraulic impact is caused by pressure. Connecting Rod and stubble have extrusion characteristics. Although the connecting Rod may break after the Piston Bites the cylinder, the Piston must be stuck in the cylinder. After holding the connecting rod broken is even more different, connecting rod big head and crankshaft have serious wear and tear, causing the breaking force belongs to the Shear Force, stubble is not the same. Finally, before holding the axle and biting the cylinder, the motor will operate over-load, the motor will heat seriously, and the thermal protector will act.

Second, the liquid source obviously, can cause the compressor to hit the liquid is nothing more than the following sources:

Obviously, the liquid that can cause compressor fluid to hit is nothing more than the following sources:

• return liquid, which is liquid refrigerant or lubricant returned to the compressor from the evaporator;

• Foam when starting with liquid;

• too much lubricant in the compressor.

Article collation comes from "Refrigeration Encyclopedia" ,

Cold and warm life binger accompanied -

Influence of evaporation and condensation pressure on refrigeration system 2020-01-09

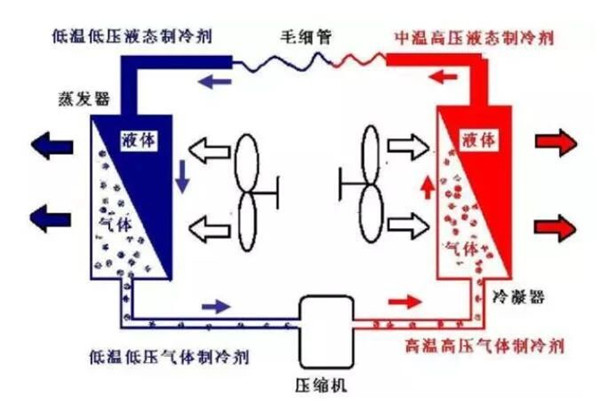

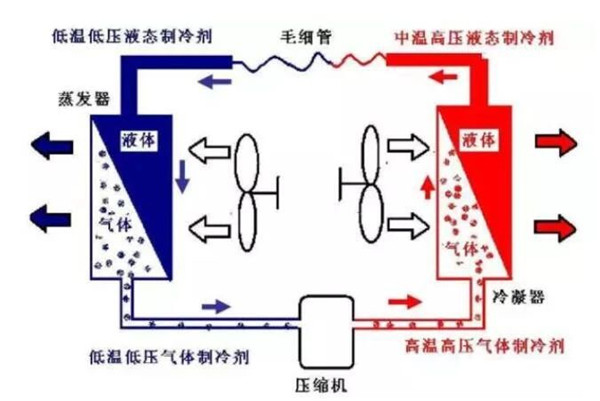

Influence of evaporation and condensation pressure on refrigeration system 2020-01-09When a failure occurs in a refrigeration system, it is generally impossible to see directly where the failure site occurs, nor is it possible to dissect and dissect the components of the refrigeration system one by one. Only by looking at the surface can abnormal phenomena be found in operation, for a comprehensive analysis. It is very important to measure the pressure and temperature of the refrigeration system.

1, Suction pressure and exhaust pressure: Refrigeration System in operation can be divided into high and low pressure two parts. Exhaust pressure refers to the exhaust pipe at the compressor outlet refrigerant gas pressure. The compressor suction pressure is called suction pressure, suction pressure close to the evaporation pressure. The difference between the two is the flow resistance of the pipeline.

For convenience, the evaporating pressure and condensing pressure of the refrigeration system are detected at the suction and exhaust ports of the compressor. That is often called the compressor suction, exhaust pressure. The purpose of measuring the suction and exhaust pressure of refrigeration system is to obtain the evaporating temperature and condensing temperature of refrigeration system, so as to obtain the running status of refrigeration system.

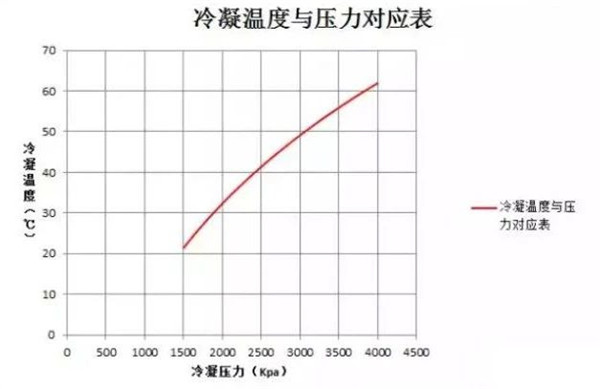

2. Condensation pressure: Condensation pressure is the pressure at which the refrigerant condenses the gas into a liquid in the condenser. Since the pressure inside the condenser in the refrigeration system can not be measured, refrigerant in the exhaust pipe and condenser pressure drop is very small, so regardless of design commissioning or maintenance, generally think that the exhaust pressure is approximately equal to condensation pressure. Condensing temperature versus refrigerating capacity: Let's look briefly at the relationship between the condensing pressure of R22 refrigerant and the condensing temperature:

As can be seen from the diagram, the condensing temperature and condensing pressure are in direct proportion, the condensing pressure and condensing temperature are corresponding; the lower the condensing pressure (high pressure) , the lower the condensing temperature; the higher the condensing pressure (high pressure) , the higher the condensation temperature. Knowing the condensing pressure, we can look up the table and get the value of the condensing temperature. Heat load and condensation pressure relationship: This is simply the condensation side of the load and condensation pressure relationship. In a constant operating condition (refrigerant flow) , the greater the heat load, the higher the condensation pressure, and vice versa. We can imagine that when you design the condenser small (heat load is relatively large) , the refrigeration system is very easy to high-pressure alarm. The influence factor of refrigeration system pressure 1, the factor of low suction pressure: The suctionpressure is lower than the normal value, the factors include insufficient refrigeration capacity, small cooling load, small expansion valve opening degree, low condensing pressure (refers to the capillary system) , and the filter isn't working. High Suction pressure factors: Suction pressure higher than normal, its factors are too much refrigerant, refrigeration load, expansion valve opening, high condensation pressure (capillary system) and compressor efficiency. 2, exhaust pressure, high exhaust pressure factors: When the exhaust pressure is higher than the normal value, there is generally a cooling medium of low flow or high temperature, refrigerant charge too much, large cooling load and expansion valve open degree. These results result in the increase of circulating flow and the corresponding increase of condensation heat load. As the heat can not be all out in time, causing condensation temperature rise, and can be detected is the exhaust (condensation) pressure rise. When the flow rate of the cooling medium is low or the temperature of the cooling medium is high, the cooling efficiency of the condenser decreases and the condensing temperature increases. When the flow rate of the cooling medium is low or the temperature of the cooling medium is high, the cooling efficiency of the condenser decreases and the condensing temperature increases. The reason of excessive refrigerant charge is that the surplus refrigerant liquid occupies part of the condenser tube, which reduces the condensing area and causes the condensing temperature to rise. Factors of low exhaust pressure: The exhaust pressure is lower than the normal value. The factors include low efficiency of the compressor, insufficient refrigerants, small cooling load, small expansion valve opening, unblocked filter, including expansion valve filter screen and cooling medium temperature low. Above several kinds of factors all can cause the system the refrigeration flow to drop, the condensation load is small, causes the condensation temperature to drop. From the above suction pressure and exhaust pressure and exhaust pressure changes, there is a close relationship between the two. In general, when the suction pressure rises, the exhaust pressure rises, and when the suction pressure drops, the exhaust pressure drops. Also may estimate from the suction pressure gauge change the exhaust pressure approximate situation.

Warm and cold life, Binger company!

-

-

-