News Center

- Operating parameters of air conditioning water system and refrigeration system

- date: 2020-03-18 hits:1273

-

Unit Working Power Supply Unit working power supply is 380V / 50Hz / 3n, its fluctuation range is between 360V ~ 420V. However, the operation of the unit has strict requirements on power supply: Power supply three-phase voltage imbalance should not be greater than 2, power supply three-phase current imbalance should not be greater than 10. Voltage is too high or too low, will cause the unit motor running current is too large, serious will burn out the unit motor.

Three-phase voltage unbalance calculation method: For example, the unit rated voltage is 380V, the measured three-phase voltage is: A-B 386V; A-C 385; B-C 382V; namely 386-3806,385-3805,382-3802. Three-phase voltage imbalance 63801001.6, that is normal (three-phase current imbalance calculation method is the same) . 2. The operating parameters of circulating water system should check the pressure difference between the inlet and outlet of chilled water and cooling water before starting up, which should be between 0.08 MPA and 0.15 MPA. If the inlet pressure is 0.4 MPA, the outlet pressure should be between 0.32 MPA and 0.25 MPA. The pressure difference is too small, that unit water flow is not enough, at this time, we should check whether the pump is working properly, whether the valve is open normally, whether the water system has air, whether the water system filter (y grid) is blocked, etc. . Do not turn on the machine until the water supply is confirmed to be normal. If the water supply is not normal, the unit will not be long after the start-up "low evaporation temperature" alarm and protective shutdown. During the normal operation of the unit, we should pay attention to the temperature difference between the inlet and outlet of the chilled water and the cooling water, which should be between 3 °C and 5 °C. If the temperature of the frozen water inlet is 15 °C, the temperature of its outlet water should be between 12 °C and 10 °C. If the temperature difference is too small, the heat exchange effect of the heat exchanger of the unit is poor. At this time, we should check whether the water quality is normal, whether the heat exchange pipe is dirty and dirty, and so on, we should check whether the normal operation of the pump, the opening of the valve is normal, whether the water system has air, water system on the filter (y grid) is blocked, etc. . Time is not long the unit will be "low evaporation temperature" alarm and protective shutdown. We should pay attention to observe the difference between the outlet temperature of chilled water and cooling water and the refrigerant temperature of evaporator and condenser should not be more than 2.5 °C. If the outlet temperature of the freezing water is 10 °C, the outlet temperature of the evaporator should be between 8 °C and 10 °C, and the outlet temperature of the cooling water should be between 30 °C and the outlet temperature of the condenser should be between 28 °C and 30 °C. The smaller the temperature difference is, the better the heat exchange effect of the unit heat exchanger is. The larger the temperature difference is, the worse the heat exchange effect of the unit heat exchanger is.

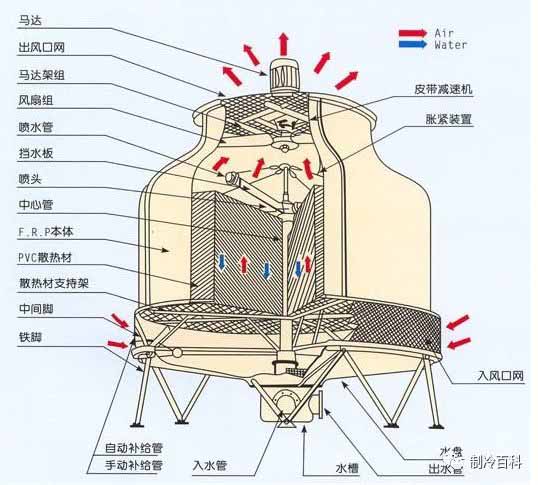

We should pay attention to observe the temperature difference between the inlet and outlet water of the Cooling Tower, which should be between 3 °C and 5 °C. If the inlet water temperature of the cooling tower is 30 °C, the outlet water temperature of the cooling tower should be between 25 °C and 27 °C. The temperature difference is too small, that the cooling tower cooling effect is poor. In another case, when the inlet temperature of the cooling tower is higher than the ambient temperature, the difference between the ambient temperature and the outlet temperature of the cooling tower should not be more than 3 °C. If the ambient temperature is 34 °C and the inlet water temperature of the cooling tower is 37 °C, the outlet water temperature of the cooling tower is about 34 °C. At this time, higher than our unit normal operating temperature requirements, we do not think that the cooling tower cooling effect is not good, in fact, this is normal. Because the cooling tower itself does not have the function of cooling, it is only the auxiliary cooling water to the environment space, so the water temperature of the cooling tower is close to the environment temperature, it should be the best working state of the cooling tower. Three, refrigeration system's main parameter refrigeration system's debugging is adjusts the system operation parameter to the request scope. The main parameters of refrigeration system are: evaporating temperature and pressure; condensing temperature and condensing pressure; compressor suction and exhaust temperature; compressor suction and exhaust pressure; oil temperature; oil filter pressure difference. These operating parameters are not fixed, but change with the change of the external conditions. Therefore, when the refrigeration unit is debugged, the operating parameters must be adjusted according to the external conditions and the characteristics of the unit so that they can operate under reasonable, economical and safe values. Evaporation temperature and pressure the evaporation temperature and pressure are determined according to the user's requirements. The evaporating temperature of the unit should be determined according to the temperature requirement and working characteristics of the cooling medium. For the refrigeration capacity of the compressor, when the condensing temperature is fixed, the lower the evaporating temperature, the smaller the refrigeration capacity, due to insufficient cooling capacity, so that the cooling medium temperature can not be reduced. While the temperature difference is smaller, the heat transfer effect is poor, although the compressor cooling capacity increases, but the evaporator heat exchange is not sufficient. Therefore, we should choose the temperature difference reasonably according to the different forms of refrigeration equipment. According to the standard of JB / T4329-97 volumetric cold water (heat pump) units in China, the nominal working conditions of chillers are cold water inlet temperature 12 °C, outlet water temperature 7 °C, cooling water inlet temperature 30 °C and outlet water temperature 35 °C.

As a result of increasing the temperature of the cold water out of the unit is very beneficial to the economy. In operation, the temperature of cold water should be raised as much as possible when the requirement of air conditioning is met. If the cold water outlet temperature is not 7 °C for long term operation, the required cold water outlet temperature should be specified in the contract. Therefore, in the actual operation of the unit, according to the specific requirements of the air-conditioning object, the cold water temperature can be raised or appropriately lowered. In general, the evaporation temperature is 2 ~ 4 °C lower than the cold water outlet temperature, then the evaporation temperature is controlled in the range of 3 ~ 5 °C. For evaporators with cooled liquid medium, the evaporating temperature should be 4 ~ 6 °C lower than that of the cooled liquid medium. The difference between the evaporating temperature and the temperature of the cooling medium is actually the opening of the throttle valve. At present, there are commonly used throttle manual throttle, thermal expansion valve, constant pressure expansion valve, float ball valve, etc. . When we debug and run, we mainly observe the change of evaporation pressure to judge whether the expansion valve opening is suitable. If the valve opening is too small and the liquid supply is insufficient, the evaporating pressure and temperature will drop, the compressor will draw in too hot, the exhaust temperature will also rise, and if the liquid supply is too much, the evaporating pressure and temperature will both rise, and the excessive liquid, it will also cause the compressor to have the liquid strike accident. Therefore, it is one of the main methods to control the evaporation temperature and pressure in operation to control the opening degree of the throttle valve correctly. In addition, if the heat exchange area of the evaporator is too small or if there is dirt on the inner and outer surfaces, the evaporation temperature will be reduced when the cooling load and the capacity of the compressor are not changed, then the evaporating temperature 2, condensing temperature and condensing pressure of the refrigeration system are the pressure indicated by the high-pressure gauge. Under normal circumstances, the condensing temperature is 5-7 °c higher than the inlet temperature of the cooling water, it is 10 ~ 15 °c higher than the inlet temperature of cooling air with forced ventilation. When the evaporating temperature is constant, the condensing temperature and pressure increase, the compressor compression ratio increases, the gas transmission coefficient decreases, the refrigeration capacity of the compressor decreases, but the power consumption increases. In addition, the condensation pressure increases, the compression exhaust temperature increases. If the exhaust temperature is too high, it will dilute the compressor lubricating oil and affect the lubrication. When the exhaust temperature is close to the lubricating oil valve point, some lubricating oil will be carbonized and accumulate in the exhaust valve, which will affect the sealing performance of the valve, on the valve plate, end cover spring and so on have an impact. During the operation, the heat transfer resistance is increased and the refrigerant vapor can not be condensed in time because of the non-condensable gas such as oil film, scale on the inner surface of the condenser or a little air in the system. The general treatment method is to regularly drain oil, air and according to the water quality of regular cleaning scale. There are two ways to clean and remove the scale and reduce the condensing temperature: to reduce the water temperature of the condenser cooling water and to increase the cooling water. 3. The suction temperature and suction pressure of the compressor suction temperature is high, the exhaust temperature is also high, the specific volume of the refrigerant when it is inhaled is large, when the refrigeration capacity per unit volume of the compressor is reduced; on the contrary, when the suction temperature of the compressor is low, the refrigeration capacity per unit volume is large. But the compressor suction temperature is too low, may cause the refrigerant liquid was sucked into the compressor, so that the Reciprocating compressor produced a liquid hit phenomenon. In addition, the length of the compressor suction pipe and wrapped insulation material performance, the size of the superheat, but also have a certain impact. The suction temperature is generally controlled at 5 ~ 10 °C in the refrigerating unit, and 15 °C in the freon system with the regenerative heat exchanger. Therefore, in the operation of the machine, we must pay attention to the control of the suction temperature of the compressor, usually with the adjustment of the thermal expansion valve screw to adjust the size of the overheating. 4, compressor exhaust temperature and pressure compressor exhaust temperature is the refrigerant after compression of high-pressure superheated steam. Because the refrigerant discharged by the compressor is superheated steam, there is no corresponding relationship between its pressure and temperature. The exhaust temperature of the compressor can be read from the thermometer on the exhaust pipe. The exhaust pressure is generally slightly higher than the condensation pressure and the exhaust temperature is much higher than the condensation temperature. The exhaust temperature is mainly related to the suction temperature, pressure and pressure ratio, and increases with the increase of them. Condensing temperature and exhaust temperature are too high on the operation of the compressor is unfavorable, should be prevented. 5. The normal oil temperature of oil temperature unit is between 45 °C and 68 °C. If the oil temperature is too low, a large number of refrigerant will dissolve in the oil, will cause the unit to return oil difficult, a large number of oil in the evaporator and condenser, affect the heat transfer effect. At this point we have to adjust the oil cooler supply (water) valve to maintain the appropriate oil temperature. If the oil temperature is too high, it will reduce the viscosity of the oil, lose its lubricating effect and shorten the service life of the spare parts of the unit. At this point, we want to check whether the oil cooler supply (water) valve open normal or oil cooler supply (water) pipeline is blocked, for removal. 6, oil filter pressure difference should be less than 50 PISD. If the pressure difference is greater than 50Pisd, the unit will be "oil filter blockage" alarm and protective shutdown. It indicates that the oil filter of the unit is saturated or dirty. At this point, we need to replace the oil filter, to ensure that the normal oil supply unit.

Article Collation from the "encyclopedia of refrigeration"

cold and warm life, binger accompanied! -

pre:Analysis of operation paramete

next:Precautions for R410A refriger - back